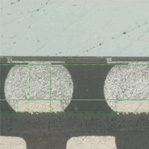

We will continue to forge the road with no preset definition. We will create to open the way to new, unseen domains with our proprietary electronic circuit technology. A road we will create to open the way to new, we call it as "OFROM OFFROAD". For over 30 years, we have continuously expanded our business, product and technological doains through repeated technological innovations. We won't do anything that serves to create limits for ourselves. Our actions are driven by the desire to continually go beyond what our customers ask of us, and lead those customers to new domains that they, too, have yet to experience. With a frontier spirit in our hearts, we will continue to blaze the "OFROM OFFROAD" that leads to the unknown.